The correct temperature setting on your soft-serve machine is critical for making a good frozen yogurt product and for extending the life of your mix. Every frozen yogurt shop owner should have a good food thermometer like this one: https://frocup.com/product/digital-thermometer/

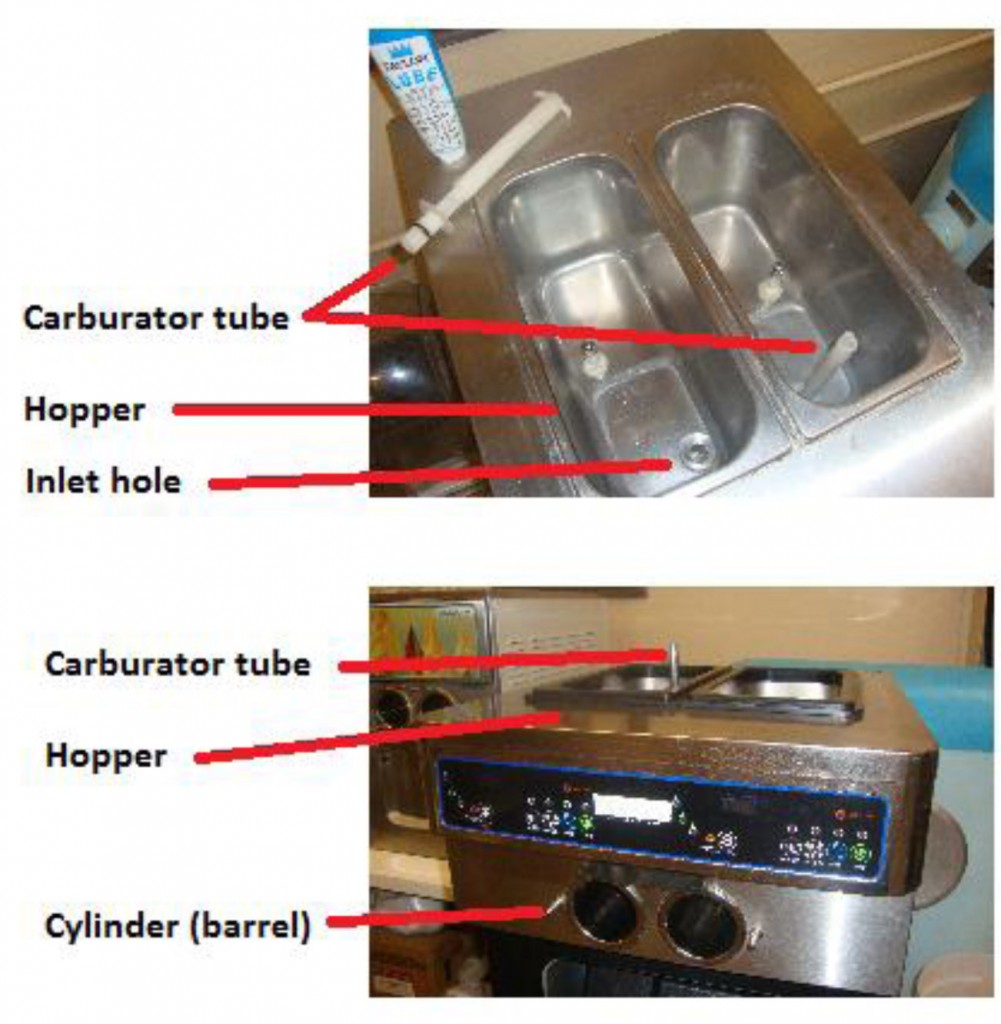

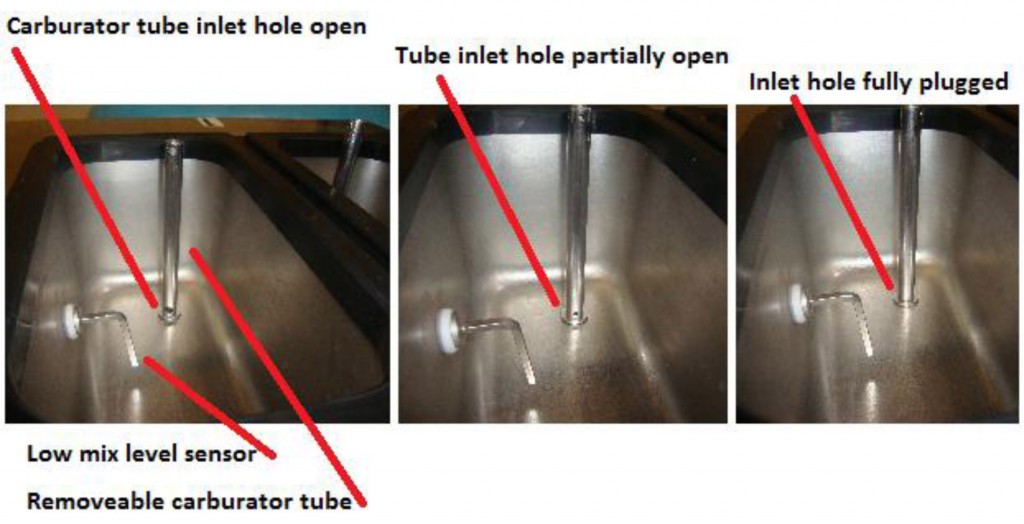

Use a thermometer to check the temperature in the hopper (the reservoir where you pour the mix) and the temperature of the product when you dispense it from the machine.

Magic Number #1

Hopper Temperature = around 35 degrees F (between 34 to 39 degrees)

The hopper temperature is critical for keeping the product fresh The temperature in the hopper should be under 40 degrees F. Any warmer and the product can go bad. It should also be warmer than 32 degrees or else the product in the hopper will freeze. If you see the product freezing in the hopper, just raise the temperature a degree or two.

Magic Number #2

Finished Product Temperature = 17-19 degrees F

The temperature of the product when it is dispensed should be between 17-19 degrees F. This would also be the temperature of the freezing cylinder. Because Nanci’s Frozen Yogurt use pure fruit sugar, the temperature for our mixes needs to be a little lower than for cane sugar mixes. A sugar mix might come out stiff at 22 degrees, but Nanci’s mixes are better at around 18 degrees. This can easily be adjusted on your machine – just consult your manual or contact the manufacturer if you need help.

If your product ever comes out wet, soupy, or melted then you need to lower the temperature. Frozen yogurt should come out stiff, creamy, and frozen (not wet). It’s amazing what a difference a couple of degrees makes.

FroCup.com

FroCup.com