When opening a frozen yogurt store, the soft-serve machines will be the largest single expense. A good machine is critical to serving good product. There are several basic things you need to know about frozen yogurt machines. This information may seem overwhelming, but given that you might spend $50,000 on your soft-serve machines, the investment of your time will be worth it.

The Basics

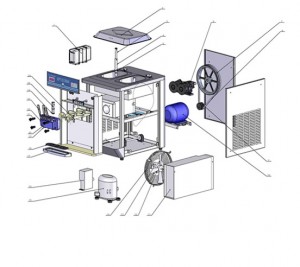

To make frozen yogurt you’ll need a commercial grade soft-serve machine (soft-serve machines and frozen yogurt machines are the same thing). Here are the basic components of the machine:

- Hopper – the area where you pour the frozen yogurt mix.

- Freezing cylinder – this is a small shaft that sits horizontal inside the machine. The mix drips from the hopper into the freezing cylinder where it freezes.

- Beaters – these are inside the freezing cylinder and they spin around to keep the mix from freezing solid. They also help whip air into the machine and make a nice creamy product.

- Front plate – this is the piece that goes on the front of the machine with the handles. It also includes the opening where the frozen yogurt is dispensed. Most machines have a star shaped design where the product comes out – giving the frozen yogurt the look we all recognize.

- Overrun – this is the air that is in the frozen yogurt mix. Air is critical to making a nice creamy product. Without overrun, the product will come out dense, icy, and won’t taste right. Visit the Training page on the Nanci’s website for a video on how to control overrun.

Machine Sizes

There are several different sizes, but for our purposes we’ll break it down into two types – floor model and counter-top model.

Floor model – these machines go all the way to the floor and are on rollers. They are either medium or high capacity and usually require 220-volts, but not always (see the section on electricity). They usually have two flavors and a twist (although they can come in a one-flavor model). For frozen yogurt shops, this is usually the best option.

Counter-top model – these machines sit on a counter or cart. They are usually low capacity to medium capacity. They are available with one flavor one two flavors and a twist. These machines can be a good option as an add on to an existing concept, like a sandwich shop.

Electricity

Most medium to high-capacity frozen yogurt machines require 220 volt electricity, although some are 115 volts. In either case, they will require different outlets than your standard home electrical outlet. They will also require higher amps than normally. Be sure to check with an electrician to see what will be required and how much it will cost.

Gravity versus Pump

This refers to how the mix gets into the freezing cylinder. With a gravity machine the hopper is at the top of the machine. The mix is poured into the hopper and then gravity pulls the mix into the freezing cylinder. With a pump machine, the hopper is pressurized and the mix is pumped into the freezing cylinder. The advantages to a gravity fed machine is that they cost less and are easy to fix. The advantages to a pump machine is that you have complete control over the amount of air you put into the final product. This can affect the quality of your product and the cost.

Gravity machines can put in up to 45% air and pump/pressurized machines can put in up to 100% air (which means equal parts mix and air).

Air Cooled versus Water Cooled

The motors in soft-serve machines produce heat and need to be cooled. The two methods for cooling are either air cooled with a fan or water cooled with pipes that run water through the machine to cool it. Overall, we recommend air cooled because they are less expensive to install and need less maintenance.

Air cooled machines don’t require any additional investment when installed, and they can be less expensive to operate (depending on your electricity costs versus water costs). Water cooled require installation of a water system, which can cost $15,000-$40,000. Water cooled machines make less noise and produce less heat. You may save on utility costs if your water costs are much lower than your electricity.

Soft-Serve Machine Companies

There are several companies that manufacture and sell frozen yogurt machines. Some are made in the United States and others are made in other countries, like China. Prices on floor models range from $5,000 to $15,000. The machines will vary in quality, warranty offered, and production capacity. The right machine for you depends on your constraints (like cash or the ability to finance) and your goals (how many machines you need, the type of concept you are doing). There isn’t always just one right answer for what machine you should buy. Contact a frozen yogurt expert at Nanci’s and we can discuss it with you. We don’t sell machines, so we’re a great neutral, third-party to talk with.

If you decide to buy machines at the low-end of the price range, make sure to machines are made with good materials and parts. For example, all machines are made with stainless steel, but steel has different grades of quality. Some machines that are made with the low-quality stainless steel can rust and cause many problems.

Also, keep in mind that regardless of the brand of soft-serve machine you purchase, you’ll want to make sure you have good access to service. All machines break at some point, and you’ll need a good technician that can work on them.

In your negotiations with machine companies be sure to ask for free in-person training and free parts (such as o-rings and machine lube). Some companies offer free Nanci’s product to off set the initial costs of the machine.

If you have any questions call Nanci’s Frozen Yogurt at 1-800-788-0808.

FroCup.com

FroCup.com