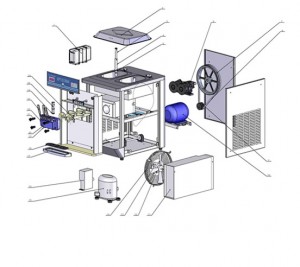

The start of a new year is a n excellent opportunity to take a look at your soft-serve machine and make sure that it is primed and ready to go for 2016! This includes not only continually cleaning your machine, but also proper lubrication and checking for any wearable parts that may have seen better days. Annually is a good time to remove the side panels and visually inspect for leaks from the motor casing and loose connections. You should also take the temperature of the hopper and freezing cylinder on standby and auto modes and compare that to what the machine is saying to check that it is calibrated correctly still. Ensuring that your machine is running properly and that it is consistently producing a quality product throughout the year will be essential to your customer base and overall margins at the end of the year.

n excellent opportunity to take a look at your soft-serve machine and make sure that it is primed and ready to go for 2016! This includes not only continually cleaning your machine, but also proper lubrication and checking for any wearable parts that may have seen better days. Annually is a good time to remove the side panels and visually inspect for leaks from the motor casing and loose connections. You should also take the temperature of the hopper and freezing cylinder on standby and auto modes and compare that to what the machine is saying to check that it is calibrated correctly still. Ensuring that your machine is running properly and that it is consistently producing a quality product throughout the year will be essential to your customer base and overall margins at the end of the year.

Cleaning your machine is an important aspect of maintenance to help the longevity of your machine. Get in the habit of cleaning your machine at least once a week. This process includes running a sanitizing agent through the machine, effectively killing any bacteria that may have grown or built up. If your machine goes weeks without being thoroughly and properly cleaned harmful bacteria may build up and could potentially lead to spoiled product.

Once the sanitizing agent is mixed with water and poured into the hopper of the machine, put the machine on the wash cycle and allow the product to cycle through the machine for a period of 5 minutes. This will allow the sanitizing agent to reach all of the nooks and crannies of the machine, killing any remaining bacteria. Be careful not to enable a feature on the machine that will freeze down the product, as the process of the water freezing could severely damage your machine. Every other week, we recommend pulling all of the machine components such as the face plate and the freezing cylinder shaft and let them soak in hot soapy water as well. The process of cleaning the machine is simple in its procedure, and it can be done any employee if they are properly trained how to do so. Check out http://frocup.com/product/sanitizer-packets/ to get started today!

freeze down the product, as the process of the water freezing could severely damage your machine. Every other week, we recommend pulling all of the machine components such as the face plate and the freezing cylinder shaft and let them soak in hot soapy water as well. The process of cleaning the machine is simple in its procedure, and it can be done any employee if they are properly trained how to do so. Check out http://frocup.com/product/sanitizer-packets/ to get started today!

Lubrication is another key technique in keeping your machine running for an extended period of time. The main component of the machine that requires lubrication is the back end of the shaft that sits deeper inside the freezing cylinder. Pull this out and pull off the rubber gasket that fits on the end of it. Lubricate around the square piece at the end of the shaft and place the gasket back onto the lubricated piece. When you pull out the freezing cylinder shaft to clean it is an excellent time to lubricate it as well. Tubes of all-purpose lube are also sold at http://frocup.com/product/machine-lube/.

There are various wearable machine parts that can become damaged and wear down over time. The scraper blades, for example, attach to the shaft on the inside of the freezing cylinder wear down and don’t scrape the edge of the cylinder with the exactness and precision that they once did. This leads to the freezing of product on the edge of the cylinder and can lower the overall quality of your product. These scraper blades are different with each individual machine company so make sure the blade is rated for your model of machine before buying replacements. You can find various machine springs, seals, and O-rings as replacement parts at http://frocup.com/product-category/supplies/.

Look for general brittleness or the wearing down of plastic parts as key points in replacement. Replacing parts before they go out will save you from costly damage to other components of the machine and keep you from having a non-functioning machine during your peak season. Understanding your machine is very important in maintaining it over time. Pulling out all of the main components and familiarizing yourself with them as you sanitize, lubricate, and replace any necessary parts will help you to keep your machine running strong throughout 2016 and beyond.

FroCup.com

FroCup.com