Every frozen yogurt operator asks how they can make fantastic and consistent frozen yogurt. They want their product to come out of the machine with the same creamy, smooth texture every day. The key to achieving this is doing two daily procedures every morning before opening.

Prime the Machine

Priming the machine refreshes the product in the freezing cylinder and hopper. Here are the steps:

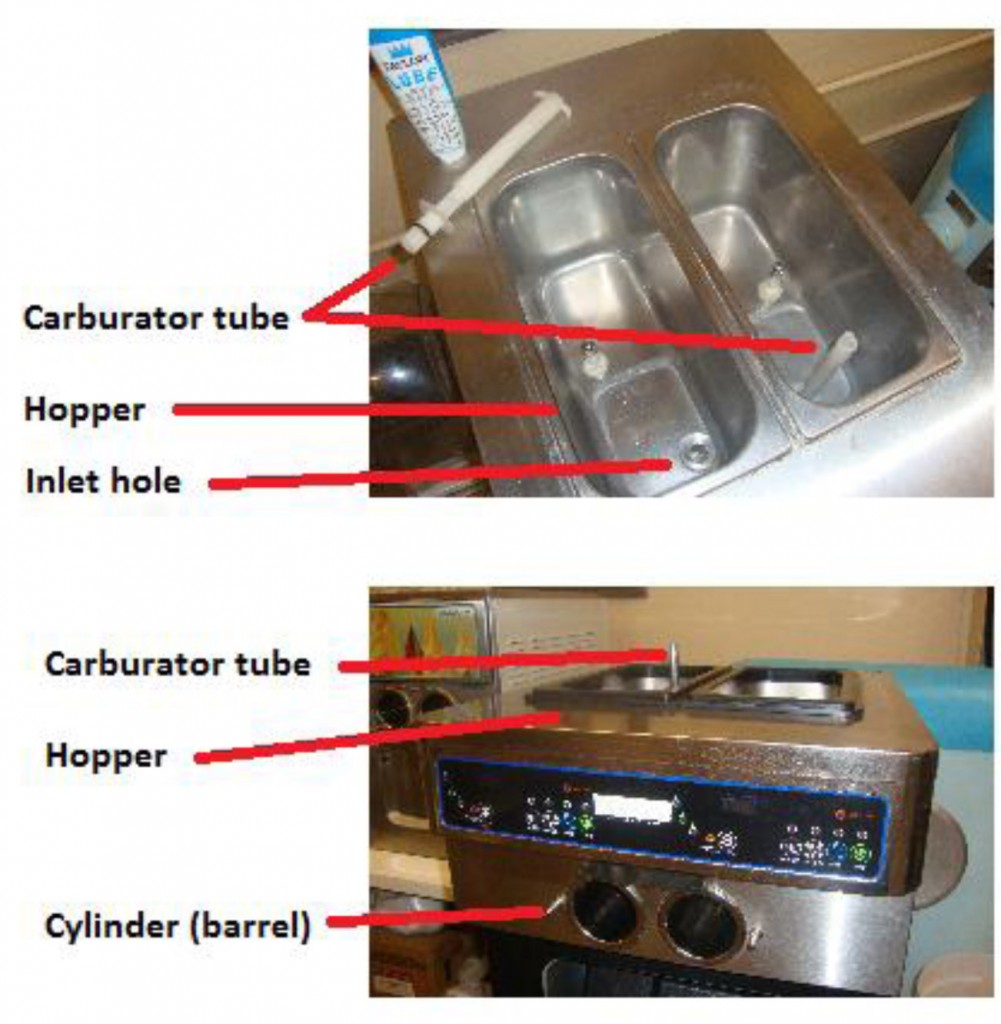

- With the machine on Standby (or Overnight) Mode, remove the air tube (carburetor tube) from the hopper.

- Stir the mix in the hopper with a small whisk.

- Dispense 1-2 quarts of liquid mix from the machine (by pulling the handle on the front).

- Pour the mix back into the hopper and stir with a whisk.

The machine is now primed and ready to have the air set.

Set the Air

With gravity machines, the mix is poured into a hopper on the top of the machine and gravity pulls the mix into the freezing cylinder. On a gravity machines you need to manually set the air, for a maximum of 35% air.

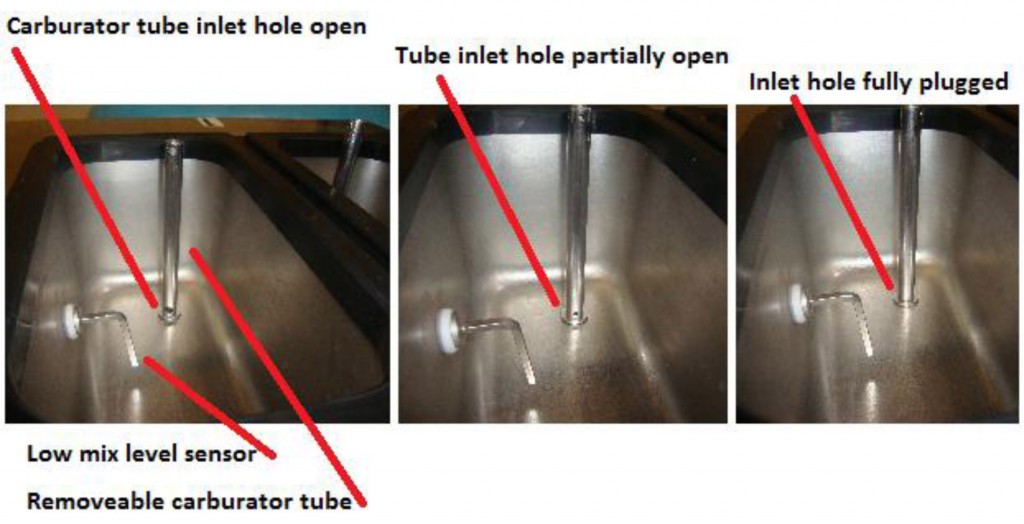

One very important piece on the machine is the carburetor tube or air tube. The air tube is a skinny tube – usually stainless steel – that you insert into the intake hole in the bottom of the hopper. Once inserted, the top of the tube sticks up out of the product allowing air to get down into the product. All air tubes have some way to shut off the product intake – either by flipping the tube over or by closing off the intake hole using a sleeve that fits around the tube.

Here are the steps to set the air:

- After you’ve primed the machine, insert the air tube with the feed hole at the top of the tube (sticking out of the mix) to stop the product from flowing into the freezing cylinder.

- Keeping the intake closed, dispense 8-10 ounces of frozen yogurt into a clean cup. This product can be put back into the hopper.

- Turn on the soft-serve machine and wait for it to freeze down and for the motor turn off.

- Once the motor turns off and the product is frozen, open the air intake either by flipping the air tube around so the feed hole is now at the bottom (submerged in the mix) or sliding the sleeve on the tube (depending on your style of air tube).

- The overrun is now set and the product should come out smooth and creamy. As long as you leave the air tube in place it will stay this way. You can repeat this process as needed.

One of the things that makes Nanci’s unique is our wide variety of flavors. We have more than

One of the things that makes Nanci’s unique is our wide variety of flavors. We have more than

FroCup.com

FroCup.com